PT. WIJAYA BANGUN RIGUTAMA (WBR) was founded on December 7, 2007, is a national private company which became part of RABANA GROUP. Operations since 2007

as a Drilling and Workover Contractor Services to many subcontractors for Oil and Gas Company. Since its expansion, the company has developed a well trained

and experiences staff of workers and professional working methods.

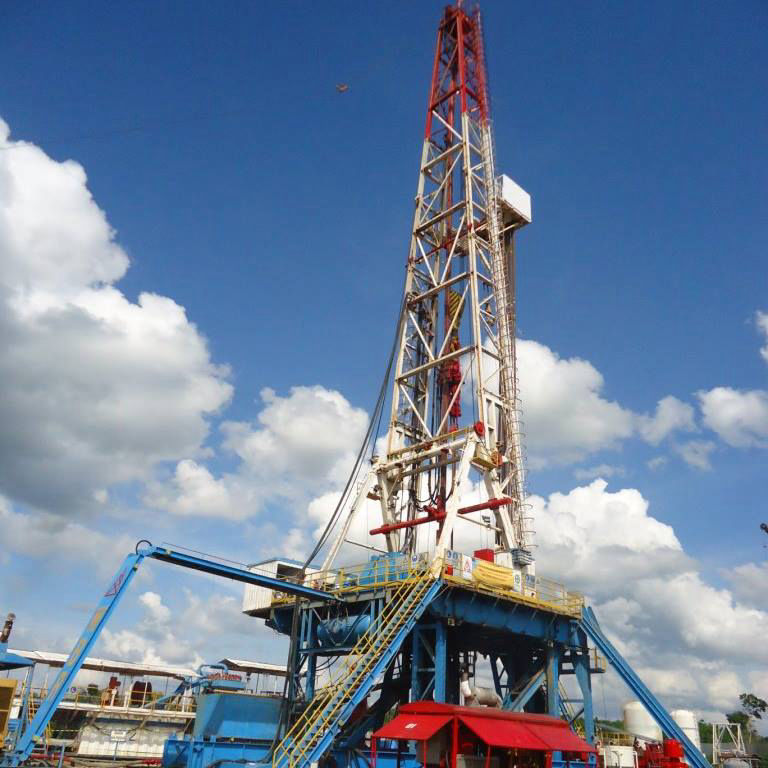

Since 2009, WBR began to stand alone for business expansion with full ownership for Rig WBR # 1 and consortium with Pertamina Drilling Services Indonesia to first Drilling Services for RIG 1000HP in PT. Pertamina EP. Then continues to direct contract with PT. Pertamina EP, Petrochina, Tately and other Oil & Gas Companies.

Currently WBR has its own Drilling RIG 1000 HP and Workover RIG 450 HP and 750 HP. WBR ready to be the leading Drilling Services Solution Provider in Indonesia.